We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Ok ✕

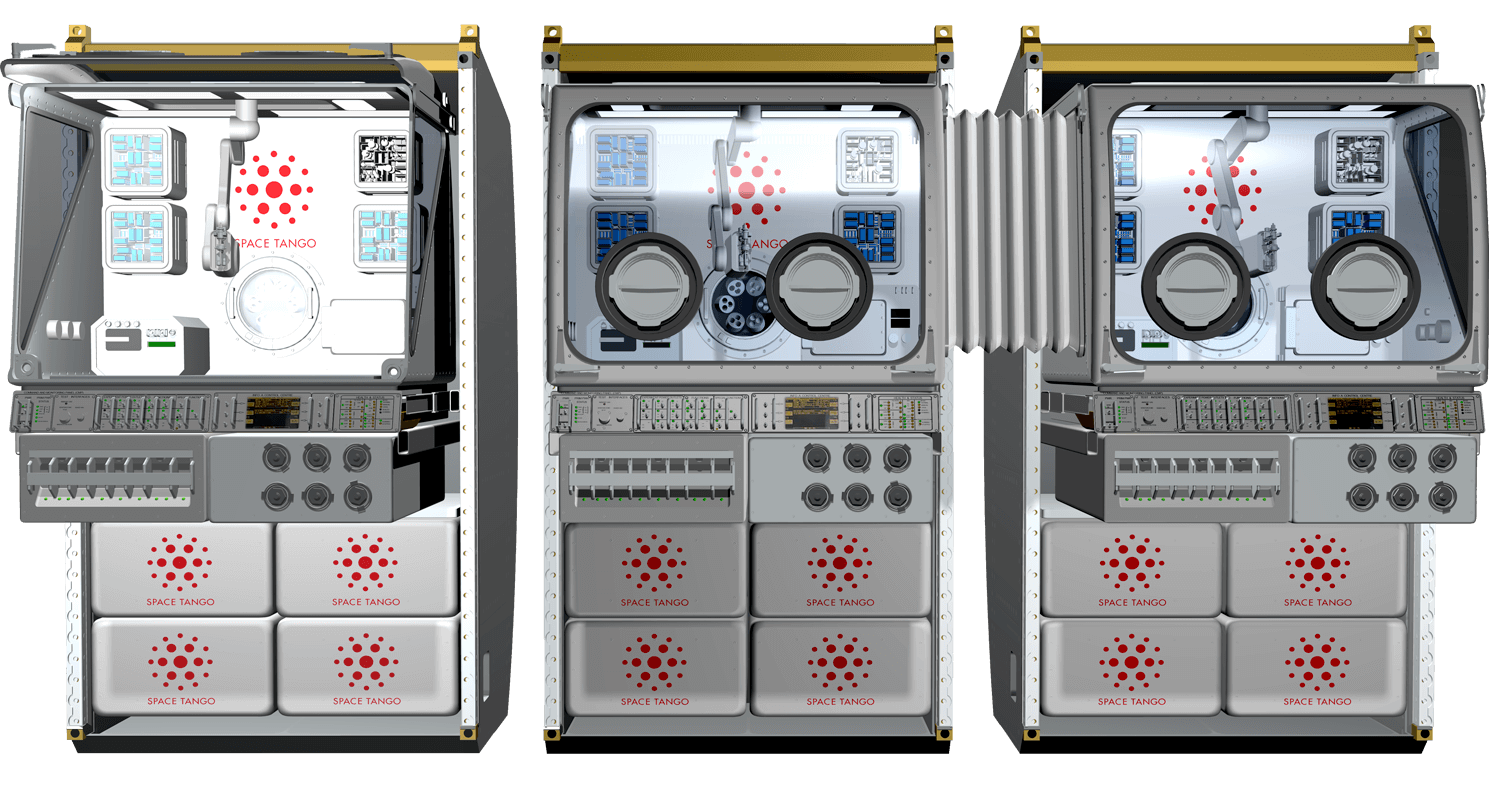

TangoBox facilities are modular from the inside out. Internally, TangBoxes can support an array of subsystem capabilities including spectroscopy, centrifuges, incubators, microplate readers, and DNA analyzers. They are also designed to accommodate analytical equipment such as single-cell genetic sequencers to characterize the effect of microgravity on related studies.

TangoBox facilities as a whole can also be attached to expand workflow capabilities. Integrated robotics enables sample handoffs between units as well as the exchange of materials and analytical equipment.

The TangoBox will provide carefully controlled systems using state-of-the-art Good Manufacturing Practices (GMP), opening the door for approval by the Food and Drug Administration (FDA) for the commercial development of patient therapeutics in space. TangoBox allows researchers to replicate sterile benchtop environments in space. It will maintain the flexibility to execute cell culture, tissue culture, chemistry, fiber optics or other materials’ R&D and manufacturing.

In addition to Space Tango’s traditional automation for thermal control, fluid dynamics, and observation; TangoBox facilities will feature an articulated, six-axis robotic arm to maximize automated workflows that replicate best practice lab procedures.