We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Ok ✕

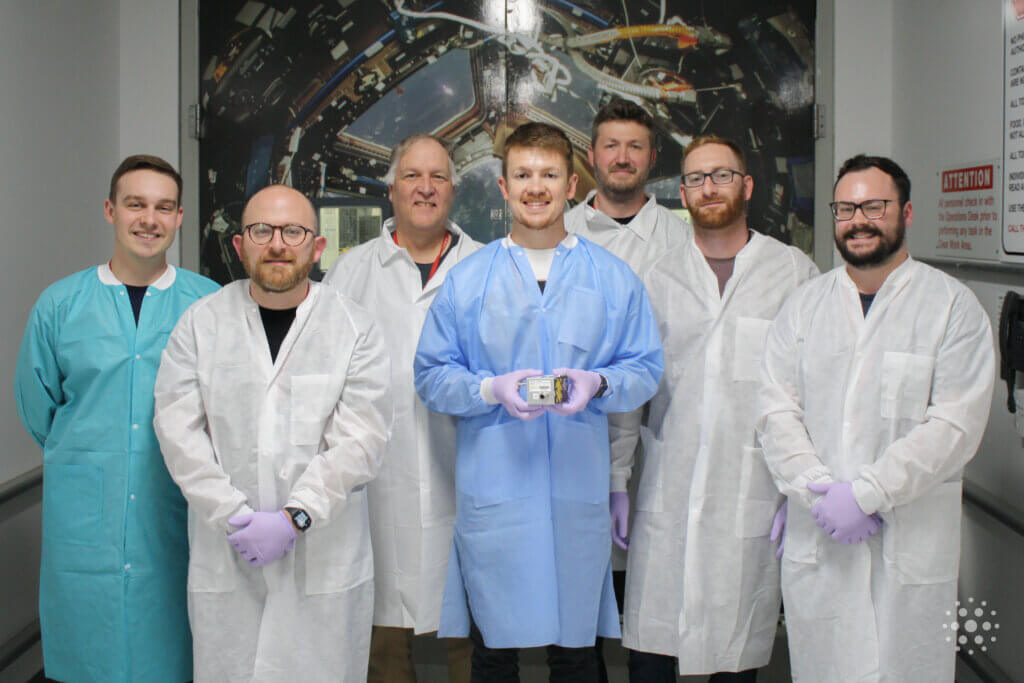

Lexington, Ky. (December 5, 2024) – Space Tango, a leading provider of automated solutions for microgravity research and manufacturing, announces the successful initial use of the recently installed Mambo facility. The facility, containing the Auxilium Microfabrication Platform (AMP-1), enabled the first-ever Digital Light Processing (DLP) bioprinter on the International Space Station to 3D print novel drug-delivery medical device in space.

Space Tango designed Mambo as a mid-deck locker architecture to host automated investigations in space. The AMP-1 bioprinter was adapted for microgravity to manufacture Auxilium Biotechnologies’ NeuroSpan Bridge— a biomimetic nerve regeneration device, designed to guide and accelerate nerve regeneration, providing a less invasive alternative for patients.

“Mambo’s success highlights the growing potential of space-based manufacturing for Earth-centric applications, reinforcing the importance of partnerships between innovative biotechnology firms and space technology leaders,” said Twyman Clements, Space Tango President. “Our collaboration with Auxilium allows us to evolve our manufacturing heritage to open new frontiers in medical innovation.”

Peripheral nerve injury from traumatic injuries results in sensory and motor dysfunction of the affected skin and muscles. When a nerve is severed, a surgical implant is required to bridge the gap, but only half of these repairs provide meaningful recovery. This experiment could create a medical device that provides a viable alternative, avoiding the risks of surgery and facilitating nerve regeneration and recovery of function.

Auxilium’s bioprinting platform features a fast, high-resolution 3D printing technology enhanced for microgravity conditions setting a new standard in regenerative medicine applications in space. Funded by NASA In Space Production Applications (InSPA), this investigation could advance space-based bioprinter technology and enable crews on future private or exploration missions to print on-demand medical devices, artificial tissues, and to treat various health conditions on-demand.

“We are thrilled to see our bioprinter arrive at the International Space Station, marking a major milestone in advancing biomedical research and innovation beyond Earth. We invite collaborators from around the globe to utilize this platform to explore groundbreaking projects that can shape the future of health and science. Together, we are redefining the possibilities of what we can achieve in space and on Earth, ” said Dr. Jacob Koffler, PhD, MBA, CEO of Auxilium.

Microgravity’s unique properties allow for enhanced structural precision and material integration that are otherwise difficult to achieve on Earth due to the force of gravity. Space Tango has a proven heritage of over 270 investigations and aims to amplify the data and product output in microgravity, facilitating commercial pathways for human health applications and advancing space-based manufacturing as a viable supply chain. Data and insights collected from Mambo’s inaugural investigation will enable future ISS investigations and will operate as a supply chain pathfinder for capabilities on future commercial space stations.

###

About Space Tango

Space Tango is an industry leader in automated systems in the pursuit of health and technology manufacturing in space. Since 2017, Space Tango has provided facilities to support iterative R&D and manufacturing in microgravity environments. Through an integrated and intuitive approach, Space Tango works alongside its diverse partner base to embrace pathways to production. For more information, visit www.spacetango.com.

About Auxilium Biotechnologies

Auxilium Biotechnologies is a pioneering biotechnology company dedicated to developing innovative solutions to treat traumatic injuries to the nervous system. With a focus on innovation and collaboration, the company develops cutting-edge bioprinting solutions and implantable medical devices to improve lives worldwide.

Press Inquiries

Danielle Rosales

press@spacetango.com

(833) 428-2646